New electrification options from Danfoss are addressing effectivity limitations in cell elevating work platforms and different light-duty automobiles

In electrified equipment, effectivity issues. The extra environment friendly the subsystems, the longer the machine can function on a single cost. If runtime will not be a difficulty, rising effectivity can cut back the quantity of batteries required, thereby lowering the upfront value in addition to the entire value of possession of the machine.

Whether or not working with low- or high-power equipment, OEMs are targeted on rising effectivity. Electrification began in low-voltage machines many years in the past, so it’s simple to miss these functions as key targets for optimisation. However OEMs specialising in low-voltage equipment, corresponding to cell elevating work platforms (MEWPs), have recognized know-how limitations, and system effectivity is falling wanting buyer necessities.

Danfoss noticed a significant alternative to enhance on these shortcomings. Danfoss Editron has persistently been on the forefront of the electrification transition in heavy-duty equipment, with options that assist OEMs cut back emissions, decrease working prices and enhance operator situations. Editron not too long ago launched a portfolio of low-voltage merchandise, encompassing 24- and 48- volt options, enabling the corporate to help electrification throughout a broader energy vary. These options, together with the ePowerpack and eDrive methods, are serving to OEMs unlock the whole advantages of electrification.

Designed for MEWPs, automated guided automobiles and different low-power, light-duty automobiles, Editron’s built-in low-voltage methods maximise effectivity, provide a really compact type issue, simplify machine design, combine simply with hydraulic methods, and cut back time to market. The methods characteristic excessive ingress safety rankings, making them appropriate for excessive environments.

ePowerpack for carry features

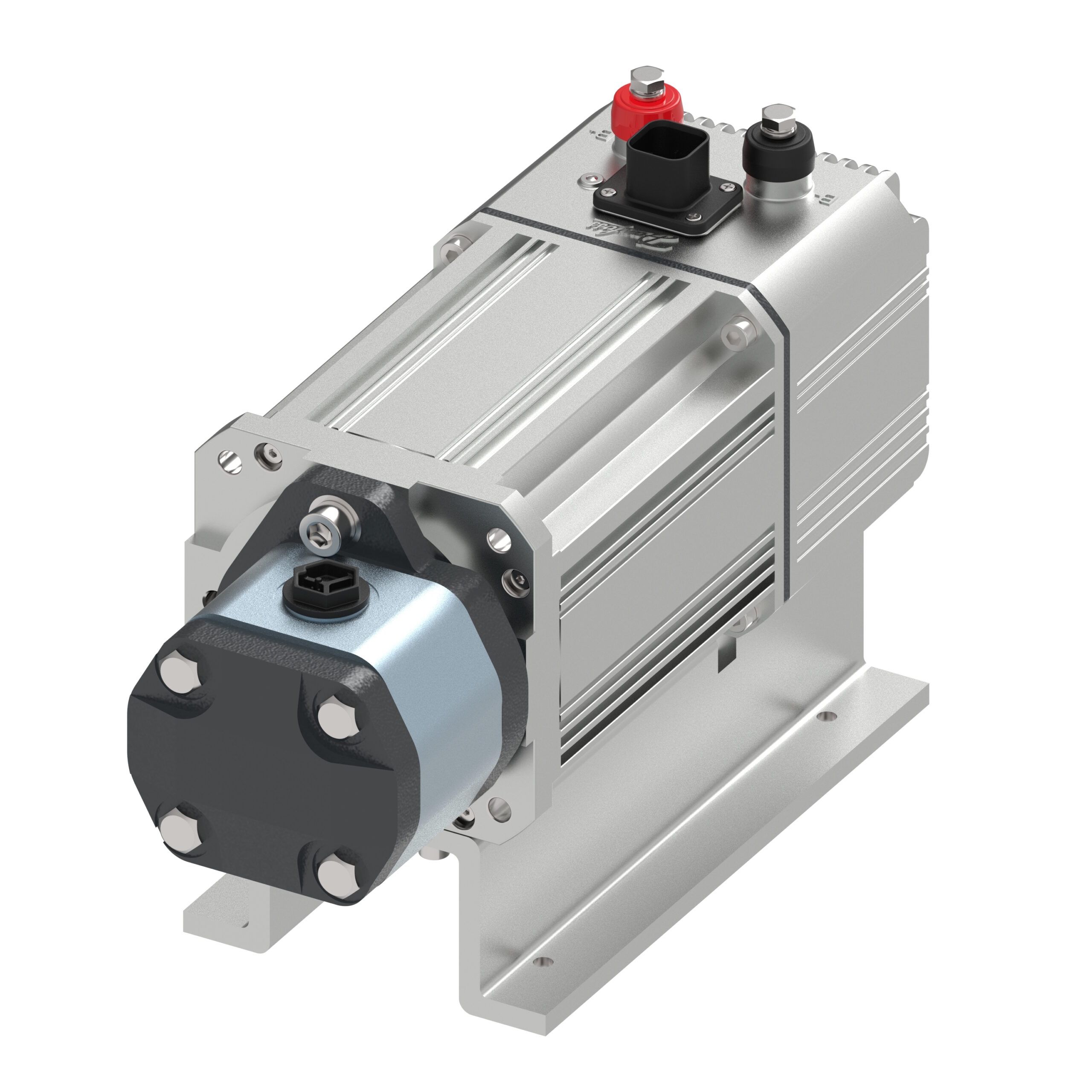

The ePowerpack is an entire system answer that powers machine carry features. It contains a everlasting magnet electrical motor, inverter, and optionally available hydraulic pump. The ePowerpack affords a number of distinct benefits. As an built-in answer, the ePowerpack simplifies and considerably reduces the variety of labour hours wanted for set up. Its compact design, which options fewer half numbers than an ordinary related design and has no extra cables or mounting plates, additional simplifies set up.

The important thing good thing about the ePowerpack is the effectivity features it unlocks. Check outcomes from the Danfoss Software Improvement Centre present that its progressive design, with an power restoration possibility, reduces power consumption by at the very least 20% in comparison with an ordinary answer. In addition to decreasing the variety of charging hours and maximising battery runtime, this could cut back working prices. Alternatively, clients can select to decrease design prices by lowering battery dimension whereas reaching the identical variety of working hours. Whichever manner clients select to make use of these effectivity features, the ePowerpack delivers decrease whole value of possession.

eDrive for propel features

The eDrive is an built-in system answer for propel features that consists of a everlasting magnet electrical motor, discount gearbox and microcontroller unit. Designed to be essentially the most compact drive answer available on the market, the eDrive affords the identical set up benefits because the ePowerpack. It additionally maximises system effectivity, providing peak effectivity of 94% in comparison with 85% for aggressive AC induction motor methods. It maintains excessive effectivity all through its working vary, with system effectivity 17% to 31% greater than AC methods at varied speeds. Common effectivity enchancment is 20%.

With overspeed safety and superior management, the eDrive delivers a smoother, higher driving expertise for operators. Its excessive controllability prevents rollback throughout hill begins and stops, whereas its excessive energy permits gradeability of as much as 30% and speeds of as much as 6.4km/h in MEWPs. The eDrive is provided with an electromagnetic braking system that’s sturdy and replaceable together with a sturdy gearbox, minimising upkeep and rising reliability.

Electrification options for each want

OEMs designing low-voltage functions now not have to compromise between sustainability, effectivity, and value. With the brand new Editron vary of low-voltage options, Danfoss can provide an answer customised to particular person wants. From scissor lifts and growth lifts to mini wheel loaders and excavators, Danfoss has the experience to develop the very best electrification answer for every utility.

To seek out out extra, iVT Expo guests can meet Danfoss Energy Options at Stand 610